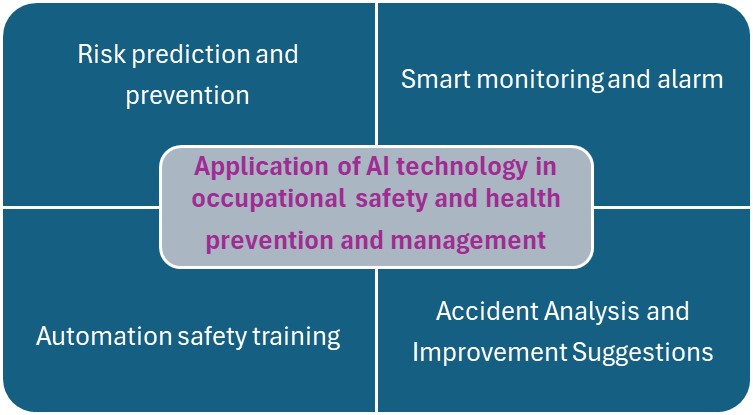

With the rapid development of artificial intelligence (AI) technology, all walks of life are actively exploring its application potential, especially in the field of occupational safety and health (OSH). Traditional occupational safety and health management mainly relies on manual supervision, written reports and regular inspections. Although this method is effective, it still has problems such as slow response, human negligence and difficulty in processing large amounts of data. The introduction of AI technology can greatly improve the accuracy and efficiency of workplace safety management and help companies establish more complete prevention mechanisms. This article will explore the four major applications of AI in occupational safety and health prevention management, including risk prediction and prevention, intelligent monitoring and alarm, automated safety training, and accident analysis and improvement suggestions.

1. Risk prediction and prevention

AI’s machine learning and data analysis capabilities can help companies predict potential occupational hazards and take preventive measures in advance. For example, by analyzing past accident records, equipment maintenance data, and environmental monitoring information, AI can build risk assessment models to predict the time, location, and cause of possible accidents. In addition, AI can monitor safety risks in factories, construction sites or storage facilities in real time through sensors and Internet of Things (IoT) technology, such as overheating of machinery and equipment, gas leaks or slippery floors. Once AI detects an abnormal trend, it can issue an early warning, allowing managers to take appropriate preventive measures and reduce the chance of accidents.

2. Smart monitoring and alarm

Traditional safety monitoring systems usually require manual inspections or fixed-time monitoring, while AI can automatically detect safety hazards in the work environment through computer vision, deep learning and IoT technology. For example, in high-risk workplaces such as construction sites, manufacturing plants, or chemical laboratories, AI monitoring systems can use cameras to analyze employee behavior in real time to detect whether someone is not wearing proper protective equipment (such as helmets, goggles, etc.), whether they have entered dangerous areas, or even whether they are driving fatigued or operating machinery improperly. When AI detects irregularities or potential dangers, it can immediately send out an alarm to notify on-site staff and supervisors to ensure that the problem can be handled in a timely manner. This intelligent monitoring method not only improves the accuracy of supervision, but also reduces the risks caused by human negligence.

3. Automation safety training

An important part of occupational safety and health management is to provide safety training to employees to ensure that they can comply with relevant regulations and operate equipment correctly. However, traditional training methods are often too rigid and cannot meet the learning needs of different employees. AI technology can improve training effectiveness through personalized learning systems and virtual reality (VR) technology. For example, AI can analyze employees’ knowledge and provide tailored training content for different positions, experience, and learning abilities. In addition, through VR and AI simulation technology, employees can learn how to respond to emergencies such as fire, mechanical failure or leakage of hazardous materials in a safe environment, thereby improving their ability to respond. This interactive learning method not only deepens employees' understanding, but also effectively reduces risks and costs during the training process.

4. Accident Analysis and Improvement Suggestions

Even if various preventive measures are taken, occupational safety accidents may still occur. Therefore, post-accident analysis is crucial to prevent similar incidents from happening again. AI can analyze incident reports, employee feedback, and surveillance data through natural language processing (NLP) technology to identify the root causes of incidents. For example, AI can quickly sift through large amounts of data to find out which factors are most likely to be associated with accidents, whether they are caused by equipment aging, human operating errors, or environmental factors. In addition, AI can also provide improvement suggestions, such as optimizing workflows, increasing the frequency of equipment maintenance, or strengthening safety training for specific types of work, to help companies continuously improve workplace safety. Through this data-driven approach, companies can formulate safety policies more scientifically and reduce the incidence of future accidents.

The application of AI technology has brought revolutionary changes to occupational safety and health management. From risk prediction, intelligent monitoring, automated training to accident analysis, AI can provide more accurate and efficient preventive management measures. Through AI, companies can not only reduce the occurrence of work-related injuries and accidents, but also improve employees' safety awareness, reduce management costs, and improve the overall working environment. With the continuous advancement of AI technology, its application in the field of occupational safety and health will become more extensive. In the future, companies will be able to more effectively protect the lives of their employees and improve safety standards in the workplace.